Tracking and material control

With real-time mining mass balance reporting, mining operations are able to accurately track the location and value of available materials at all times. With accurate tracking, the control room can be alerted when a stockpile is overfilled or depleted and can reconcile any discrepancies back along the material flow should a problem arise.

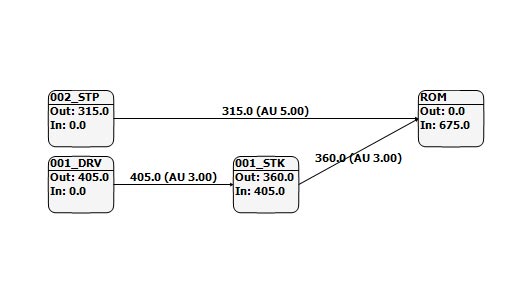

MICROMINE’s fleet management and mine control solution, Pitram is able to provide mining mass balance capability for operations wanting to accurately track their material movement. This is achieved via the materials management module which utilises mine design, survey and production data to provide real-time stockpile balances throughout the operation. Stockpile balances are updated following every material movement ensuring that the location and value of available material is known at all times.

Mining mass balance: optimised reporting

The materials management module provides a wide range of reporting options to better manage and analyse on-site mining mass balance from primary extraction locations to the mill feed stockpile. Reports are able to be generated for a variety of key material management areas, giving supervisors a better understanding of current material locations.

Stockpile management reports are able to be generated that identify the current level of stock available in real-time for any mining mass balance throughout the operation. Mining supervisors are able to set maximum and minimum levels that alert when a stockpile has been overfilled or depleted from. Following reporting, stockpiles can be calibrated to ensure the most accurate representation of the mine’s stocks are available.

Ensuring data accuracy

Validation reporting is also available that allows all material flows recorded in Pitram to be validated against a series of rules to assist identifying data entry issues. This ensures the integrity of your mining mass balance data and allows any problems with data capture or recording to be rectified.

Using Pitram, mining operations are able to accurately manage material movement throughout the mine. Accounting for mining mass balance allows for more accurate reporting and greater control of your operations on-site.

Further reading

>Learn more about Pitram’s mining mass balance solutions.